Customized Arduino Board

How to take your Arduino from Prototype to Production?

NOTE: This article/blog is Copyright TronicsZone. It cannot be reproduced without prior written approval.

In this article, we try to explain the steps involved in taking Arduino from prototype POC to production by providing custom Arduino board. It is based on TronicsZone’s experience while interacting with various customers who were initially comfortable in using Arduino to showcase their ideas, but then hit a road block very quickly when they planned to scale up to production.

Arduino as a quick Prototyping Platform

Arduino is a pretty nifty piece of hardware & originated from the popular ATmega series of Microcontrollers. It is usually one of the very first practical embedded computers that many engineers, students & hobbyists lay their hands on in modern times.

Arduino comes in many different flavours based on microcontroller capabilities (speed, flash, RAM, peripherals etc), number of I/O pins, communication options etc., like Arduino Uno, Mega, Nano and so on. That makes it extremely easy for anyone planning on getting their feet wet on Embedded Systems. It is a platform of choice for many prototyping projects & experiments that are designed for proving a concept (PoC). Many start-ups also use Arduino to build PoC prototypes to pitch to their VCs. It is highly preferred by many individuals and start-ups due to the ease of use & the quick results one can obtain from them.

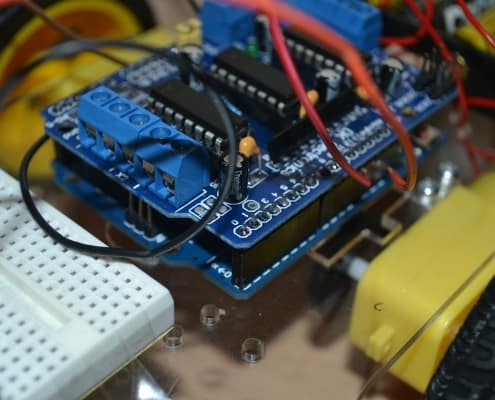

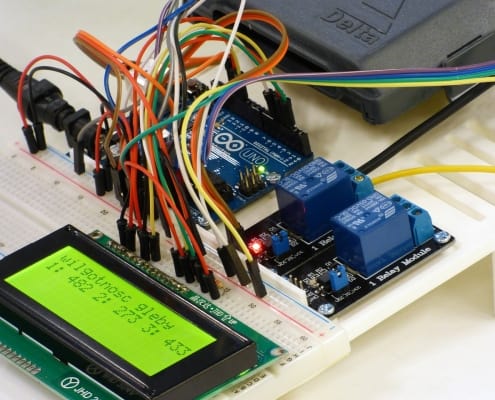

Arduino with Shields looking messy

Arduino Shields

Don’t forget that Arduino by itself can have very limited uses. What makes it so popular are various “shields” or add-on peripheral boards and the software libraries for those shields that are readily available. They plug into the Arduino main board and provide additional functionality like, motor drivers, sensors, LCDs, switches and so on. They are so much in demand that there are many small companies & individuals that make their living just by selling these shields!

Most of the PoC prototypes built by “makers” end up using several of such shields to derive the required functionality. Some shields require their own power supplies as well. So, it is not surprising to see several PoC prototypes using separate power supplies! As the complexity increases, very soon the whole setup starts to look messy. Its not just the looks, but even the costs shoot up due to redundant usage of parts & power supplies. Also, the reliability of the system is reduced since more parts means more things to go wrong. There are also several wiring & jumper cables to consider between shields causing loose connections & reliability issues.

Arduino with jumpers & shields

However, once the PoC is completed, what next?

Taking Arduino from PoC to Production

Things start getting complicated once PoC is demonstrated and there is a high level of interest in converting it into a full-fledged product.

Once a prototype has been developed using Arduino, there is not much scope for scalability. One needs to keep buying shields, use lot of jumpers, multiples power supplies and spend a lot of time assembling each unit. This is a serious scalability problem. Not to mention, the costs are high due to the inherent redundancies.

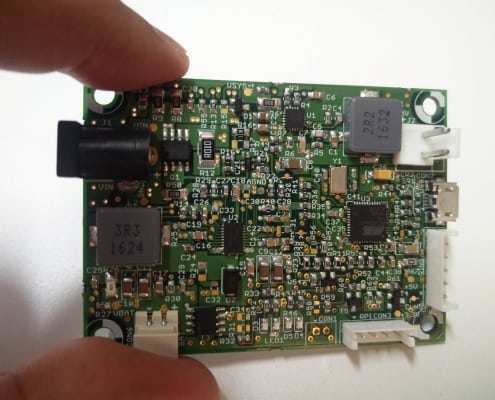

Custom Arduino Boards

Custom Arduino Circuit Board

On the other hand, since Arduino is open source, it makes an excellent candidate for customization. Tronics Zone has been involved in making custom electronics & circuit boards based on Arduino as per customer’s requirements based on their existing shields. All we need from a customer are few details like which Arduino version is being used, what are the various shields that needs to be interfaced and the I/O mapping between the Arduino and its shields. Once we get these details, we can quickly & efficiently convert the PoC prototype into a professionally looking single customized PCB board. This customized circuit board is mass manufacturable and can be taken into production very easily. The customers do not have to worry about buying Arduinos, shields, power supplies, jumpers. All that needs to be done is fabricate the PCBs, assemble all components on the PCBs.

So in summary:

Customized Arduino circuit board = Base Arduino + Shield1 + Shield 2 + Shield 3 …… + Power components + All interconnections + Additional peripherals (LEDs, buttons etc).

All in a compact professional looking form factor ready to take into production and fully scalable!

Note: This content is copyright of TronicsZone. It cannot be reproduced without prior written approval.

Read more here